Supply Chain Management (SCM) is the management of the flow of goods, services, information, and finances as they move from supplier to manufacturer to wholesaler to retailer to consumer. It involves the coordination and integration of these flows both within and among companies to efficiently deliver products to consumers. Here’s a more detailed explanation:

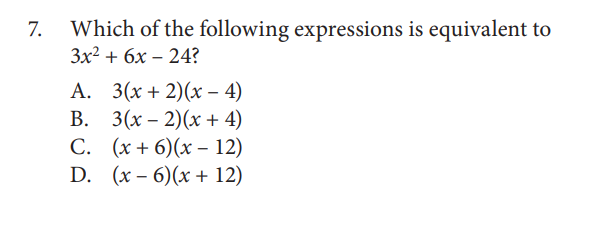

- Planning: This is the strategic part of SCM. Companies need a strategy for managing all the resources that go toward meeting customer demand for their product or service. A big piece of planning is developing a set of metrics to monitor the supply chain so that it is efficient, costs less, and delivers high quality and value to customers.

- Sourcing: Companies must choose suppliers to deliver the goods and services they need to create their product. Therefore, supply chain managers must develop a set of pricing, delivery and payment processes with suppliers and create metrics for monitoring and improving the relationships.

- Making: This is the manufacturing step. Supply chain managers schedule the activities necessary for production, testing, packaging, and preparation for delivery. This is the most metric-intense part of the supply chain—one where companies are able to measure quality levels, production output and worker productivity.

- Delivering: This is the part that many people think of as logistics. Companies must create a network of distributors that take the products to the right place. Most companies use a mix of transportation modes and choose a transportation mode based on cost, speed, and capability.

- Returning: Not all product journeys end with the customer. There are product recalls, returns of products due to defects, recycling programs for goods no longer in use, and many other reasons that may require the product to travel in the reverse direction through the supply chain.

Efficient supply chain management can lead to lower costs, better quality, and faster delivery, which gives companies a competitive edge in the market. On the other hand, poor supply chain management can result in higher costs, lower quality, and slower delivery, putting a company at a significant disadvantage.

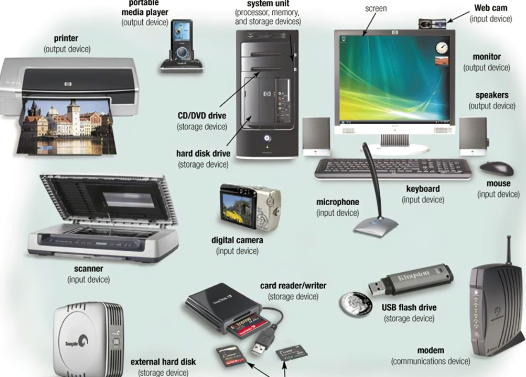

The importance of SCM has grown as business and technology have become more complex. It encompasses a wide range of activities, and it touches many other disciplines within a company—human resources, information technology, and finance, for example. All of these areas must work together. In essence, the supply chain integrates all the many departments and functions that must work together to deliver value to the customer.